Ongoing commitment

to target zero defects

Continuity of supply and continuous improvement are just some of the goals that Prima Zanetti pursues daily in its commitment to customer service, enabling it to develop products of high quality and precision. The company, with its “Target Zero Defects”, aims exactly to accomplish and maintain the manufacture and the output of goods and services with such a high level of quality that there are no defects or errors.

The idea is to improve customer satisfaction, while also leading to greater operational efficiency and long-term cost reduction through modern equipment and the ever-present concept of sustainability. Prima Zanetti then takes compliance to heart, with the achievement and maintenance of IATF 16949 and ISO 9001 certifications through the certification agency TÜV SUD Italia.

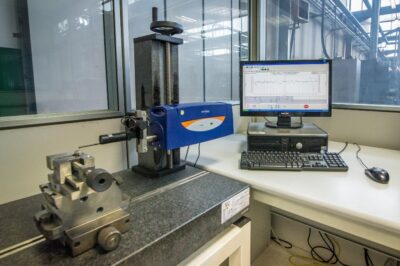

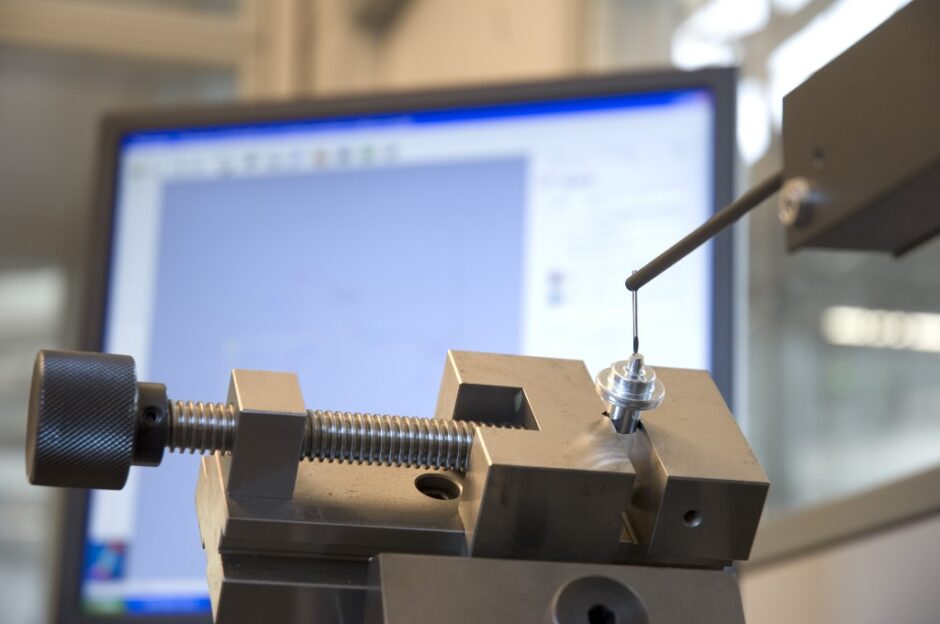

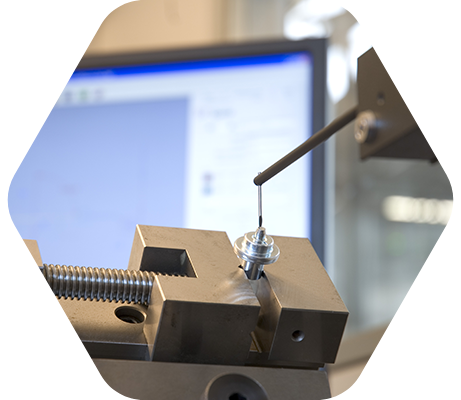

Meticulous controls with modern equipment

The production process is monitored in its entirety, from receipt of raw material to final shipment and transport, through:

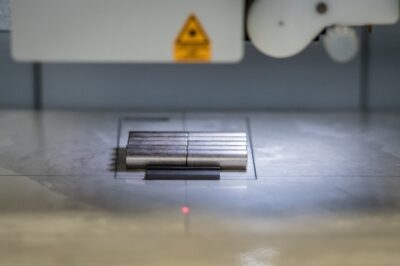

- Control and verification of 3.1 certified incoming raw material with Eddy Current system.

- Constant monitoring of plants with electronic stress control instrumentation.

- Automated in-line scrap separation systems.

- Dimensional, visual, mechanical, and surface tests performed at all stages of the production process.

- Continuous training of our operators.

High quality

Attention to and compliance with Customer requirements ensure that each component is a tangible expression of our commitment to perfection.

Client oriented

Our customers can safely plan deliveries thanks to an efficient logistics organization.

Industry 4.0

We use innovative control technologies such as electronic stress monitoring systems in forming/rolling processes.

Know-How

Design & Co-Design, our experience at customer’s service.

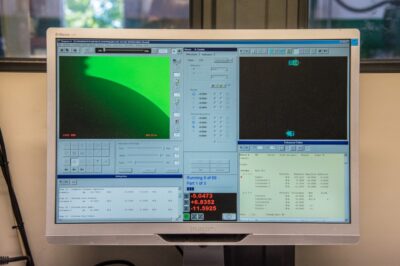

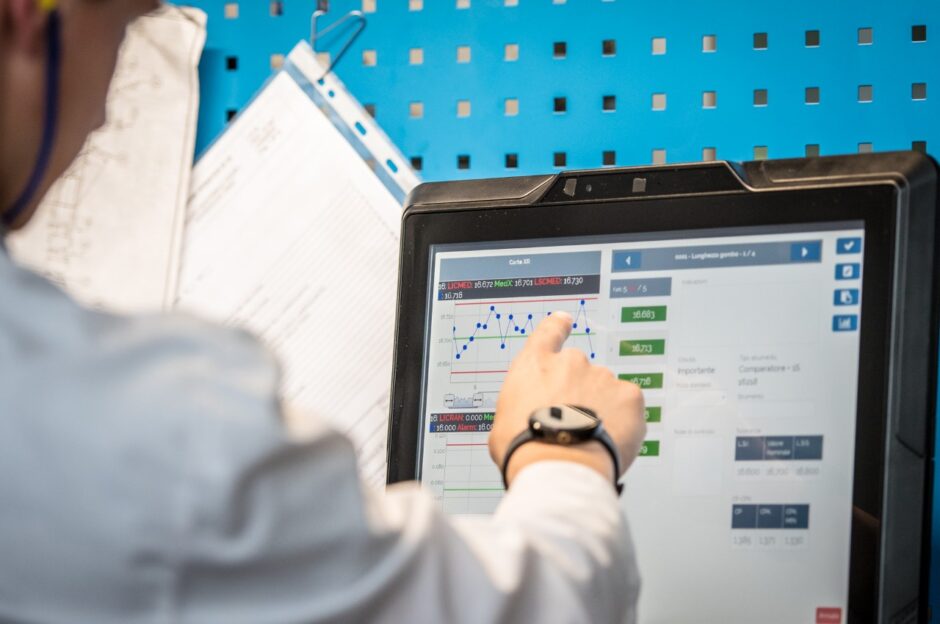

Industry 4.0 in Padua

Prima Zanetti is an Industry 4.0 thanks to the implementation of a new management software networked to all production lines. This, in addition to monitoring the plants and providing production efficiency indicators, allows to record in real time all the quality controls performed, analyzing the processes with in-depth statistical studies (CP, CPK, CMK, X-R control charts). The main purpose is to be able to pursue continuous improvement of all our processes. Prima Zanetti issues PPAP/PSW level 3 documentations, including IMDS management.

Contact us for more information or request a completely free estimate, custom made according to your needs.

High levels of quality guaranteed

Achievement and Retention of IATF 16949 and ISO 9001 certifications

Where we are

GPS coordinates:

long. 11.952138 (11° 57' 7.70'' E) - lat. 45.393598 (45° 23' 36.95'' N)