60 years of excellence

in cold forming

made in Italy

Manufacturing of high-quality small metal parts

High levels of quality guaranteed

Achievement and Retention of IATF 16949 and ISO 9001 certifications

Our company

Founded in Padua in 1961, Prima Zanetti is one of Europe's major manufacturers of precision small metal parts made to Customer drawings and specifications, such as solid/half-hollow/through hole rivets, spindles, cores, multi-diameter pins, cut-off stud balls, and threaded and/or knurled parts, obtained by cold forming a wide range of wire types.

Prima Zanetti targets European and Global markets.

Product diversification and the extreme flexibility of our machinery allow us to operate in sectors as diverse as automotive, household appliances, electromechanical, electronic, automation and construction.

We have the ambition to take our know-how all over the world. Investment in innovative technologies and the development of new projects is part of our policy of continuous improvement and is primarily aimed at achieving the characteristics of an ideal supplier in increasingly demanding markets.

Reduced costs and zero material wasted.

Not producers, but Manufacturers

of cold formed parts from wire

High quality

Attention to and compliance with Customer requirements ensure that each component is a tangible expression of our commitment to perfection.

Client oriented

Our customers can safely plan deliveries thanks to an efficient logistics organization.

Industry 4.0

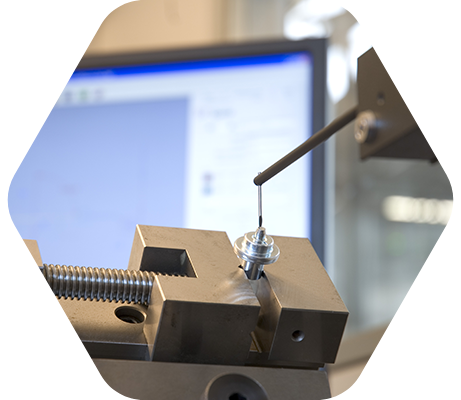

We use innovative control technologies such as electronic stress monitoring systems in forming/rolling processes.

Know-How

Design & Co-Design, our experience at customer’s service.

3 million pieces produced daily

Over 60 years of experience

356 Tons of CO2 emissions spared in 2022 // 100% Green Energy

61 Tons of CO2 compensated in 2022 // 100% of gas compensated

65% of exports in 20 Countries Worldwide

Our target sectors

High-precision small

metal parts in Padua

Prima Zanetti stands out for its versatility and expertise in a wide range of key industries, including Automotive, Electrical/Electronic, Electromechanical, and Home Appliances. With more than 60 years of experience in the high-precision small metal parts industry in Padua, the company is strongly export-oriented, with more than 65% of its turnovers coming from abroad. We are a reliable partner to numerous companies, supplying custom components to drawings in multiple industries. The ability to adapt to specific needs, along with dedication and innovation, allows us to contribute to our customers' success and maintain a prominent role in these ever-changing industries.

Automotive

Innovation in motion: we support our automotive partners with high quality fabrications. We manufacture suspension pins, cores for acoustic warning systems, and relays cores for electronics.

Electric/electronic

We manufacture rivets and solid contacts for temperature control and air conditioning systems, diode terminals for power electronic and pins for industrial connections.

Electromechanical

We have been working with companies in the industry for many years, making cores for relays and coils for civil and industrial electrical panels, as well as a wide range of fastening systems.

Household Appliances

We manufacture damper stems and fastening components for hinged opening systems mounted on washing machines, fridges, and ovens. We also manufacture pins for controlled opening of dispensing valves for gas cookers and spring pins for shells, that are installed on compressors.

Find out more about our technologies

Prima Zanetti, in Padua, performs in-house cold forming, turning, machining, rolling, knurling, threading, and complementary processing in outsourcing

Tooling department

Equipped with a tooling department that produces 90% of requirements, we guarantee short lead times and high standards of quality and precision.

Cold forming

The company has made this technology its core business, using a series of multi-station progressive machines able to perform up to 6 operations.

Rolling and machining

Mechanical completion operations to obtain a precision cold formed and machined element.

Treatments

Pre-treatment degreasing, oiling, finishing washing for steel, copper, aluminium, and brass. Wide range of thermal and galvanic treatments in outsourcing.

Sorting

We offer in-house or outsourced products checked by sorting machines equipped with optical cameras, capable of achieving 100% conformity verification.

Logistics

We put the outmost care in packaging, which is carried out according to Customer’s packaging specifications.

Where we are

GPS coordinates:

long. 11.952138 (11° 57' 7.70'' E) - lat. 45.393598 (45° 23' 36.95'' N)